[Edit May 28, 2019: The violin plot and two of the other plots below had an axis that stated micron squared and should have been millimeters squared; those are now fixed. Thanks to Mark Burness for noticing !].

As some of you know, I recently decided to make the move and get the Lyn Weber EG-1 grinder with the SSP Ultra low fines burrs. I took this decision mainly because I heard this combination generates the lowest amount of fines other than industrial roller mill grinders, but also because of its design focused on single dosing and low grind retention. I like to switch coffee every brew, so those are very nice features for me. I’ll make a more detailed post where I compare the EG-1 with my previous Baratza Forté, but in the mean time I’d like to talk about burr seasoning.

The Seasoning

If you never heard the term seasoning, it refers to the habit of grinding a large quantity of roasted coffee (or even rice) to break in grinder burrs which initially have harsh angles and corners. It is often said that this is done to prevent grind size from changing with use, and to obtain a more uniform grind distribution, which maximizes the average extraction yield of good-tasting espresso or pour over brews. When I seasoned my Baratza Forté, I did it with 12 pounds of roasted coffee at espresso grind size. Back then, I didn’t have a good way to measure the particle size distribution of my grinder, and I just supposed that I was done.

It is possible to diagnose whether you are done seasoning your grinder with a refractometer, by actually brewing coffee and noting the maximum average extraction yield you are able to reach without getting astringent taste. This typically takes me a couple of brews, and giving the limited time I had to do this I just ground a large amount of coffee and called it a day.

Now that I wrote an application to actually measure grind size distributions, I decided to take a sample of coffee every few pounds while I was seasoning the SSP burrs of my EG-1 grinder. I zeroed the grinder position at grind setting 0.0, which means that this is the point where burrs touched (I can hear burrs that start to rub against each other at grind setting 1.5). I initially started seasoning 2 pounds with a 700 RPM (revolutions per minute) motor speed and grind setting 8.5, which means that the burrs were 425 microns apart; turns out this was closer to a V60 grind size, so I went down to grind setting 5.0 (250 micron burr spacing) and 800 RPM after that. The slightly higher motor speed made sure that the motor didn’t stop from time to time as I fed a lot of coffee in the grinder. After 12 pounds, I even went a bit faster (1000 RPM) for the same reason. I sticked with this setting all the way to 24 pounds; I went all the way to 24 pounds because I heard the SSP burrs were particularly hard to break in.

I used a collection of beans from bad roast batches at my local roaster to do the seasoning, so they consisted in mix of roast profiles and bean varietals. However, after every 2 pounds of seasoning with the mixed coffee, I always took a small ~10 grams sample of the same bean, a washed Bourbon from Burundi (roasted by my friend Andy Kires at the Canadian Roasting Society), which came from a single roast batch. I always made sure to purge the grinder of any grounds from the seasoning before collecting the sample, and I ground and threw away a small amount of the Burundi just before grinding the actual sample to make sure none of the seasoning coffee was left in. I always collected the Burundi samples at grind setting 8.5 (425 micron burr spacing) with a 700 RPM motor speed.

The Particle Size Distributions

I decided to measure the particle size distribution of half the samples (every 4 pounds), because this takes a crazy amount of work; for each sample, I took 12 images that I analyzed and combined with my grind size application. I didn’t count exactly how many hours this took, but it was about 2 seasons of The Office.

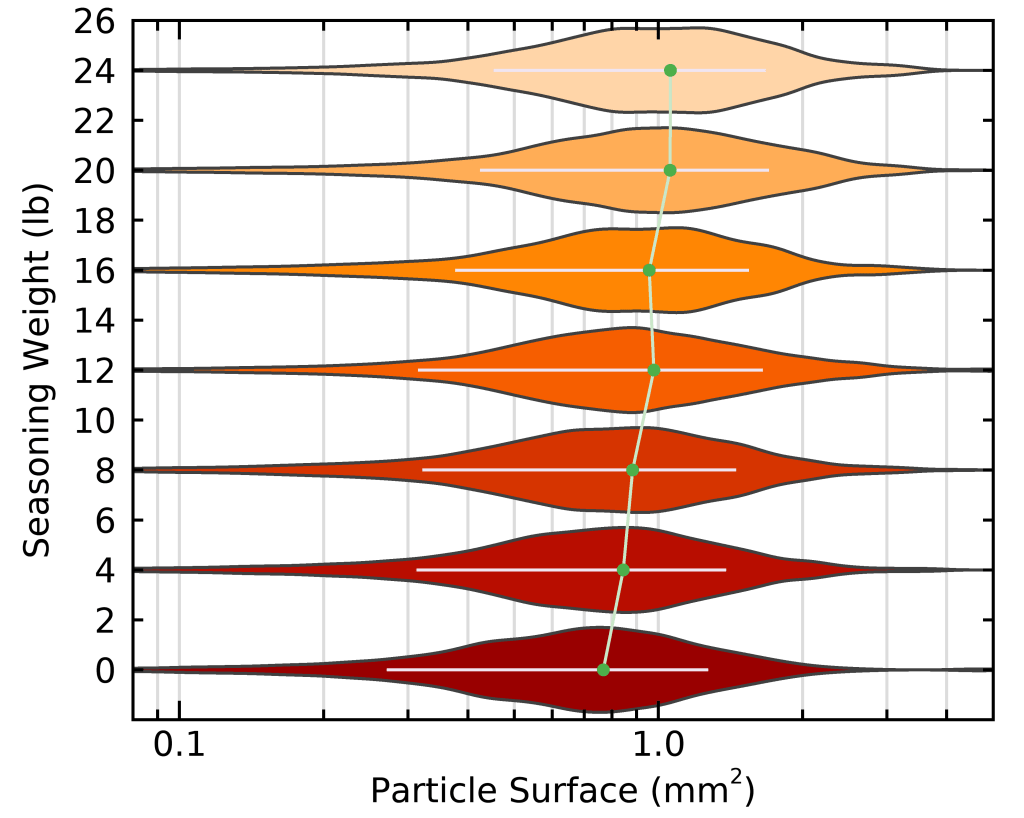

In this figure, the thickness of the horizontal band represents the total mass of the particles at each particle surface (this is called a violin plot and it’s great to compare several distributions together). This allowed me to see for the first time how the particle distribution moves to coarser particles as the burrs are breaking in. It makes a lot of sense that the distribution moves to coarser sizes, as the more rounded edges of the burr’s teeth should allow slightly coarser particles to pass through.

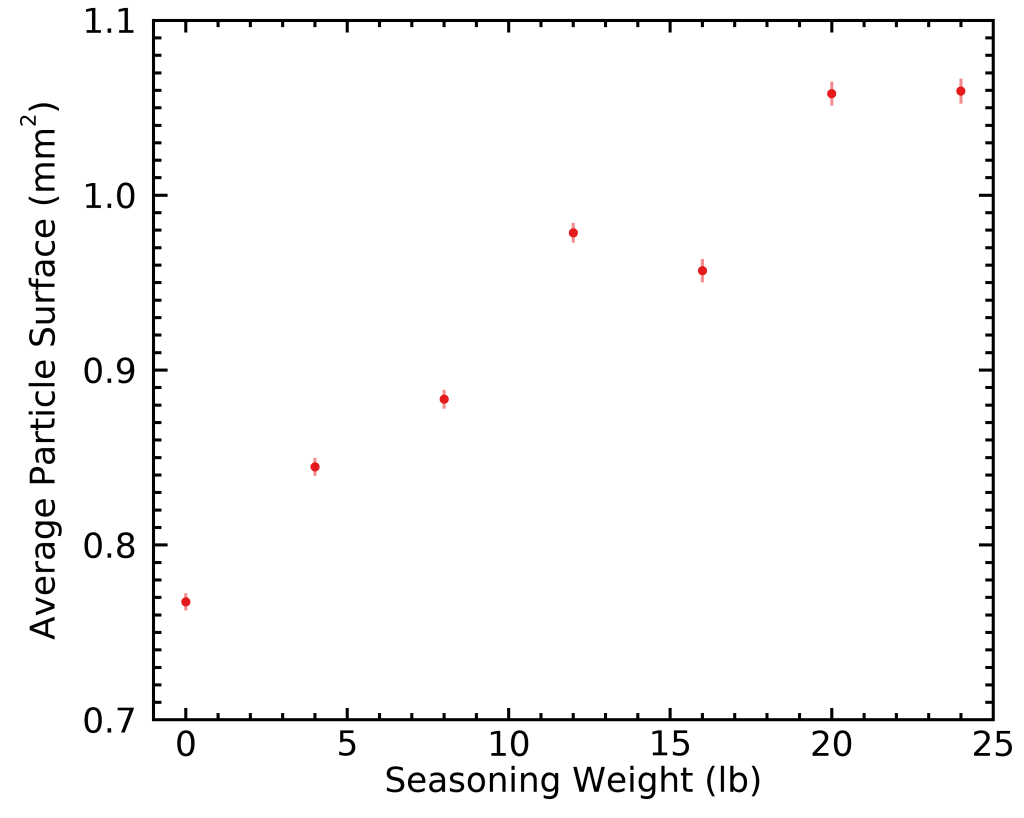

In the figure above, I show how the average particle surface changed with the total seasoning weight. The error bars are based on small number statistics (for the statistics geeks, they are based on Poisson distributions), and represent the fundamental limit in precisely measuring the average particle surface from the limited number of particles that I analyzed (typically approximately 15,000 particles, which is what 12 photos on a standard white sheet of paper gets you).

Notice how the 16 pounds data point seems off from the general trend. I strongly suspect this was caused by me forgetting to set the motor speed to 700 RPM when taking the Burundi sample – leaving the motor speed at the 1000 RPM I used for seasoning would make the particle spread distribution finer on average. This is an effect I also observed with my app, but this will be for another blog post.

One thing that I found particularly interesting is the fact that, even when the particle distribution stabilizes and stops moving to coarser particle sizes, it kept becoming more uniform. I can’t say for sure that this happens on all burrs and all grinders, but this is a good thing ! I found it amusing that I stopped seasoning within 4 pounds of where the shifting of the particle size distribution stopped being detectable with high statistical confidence with my 12 photos. One thing that hit me when I saw this figure is that it resembles a relation that exponentially approaches an asymptote, like a lot of other things in life; another example of such a relation is the concentration of water versus time in an immersion brew.

Grinder Quality Factors

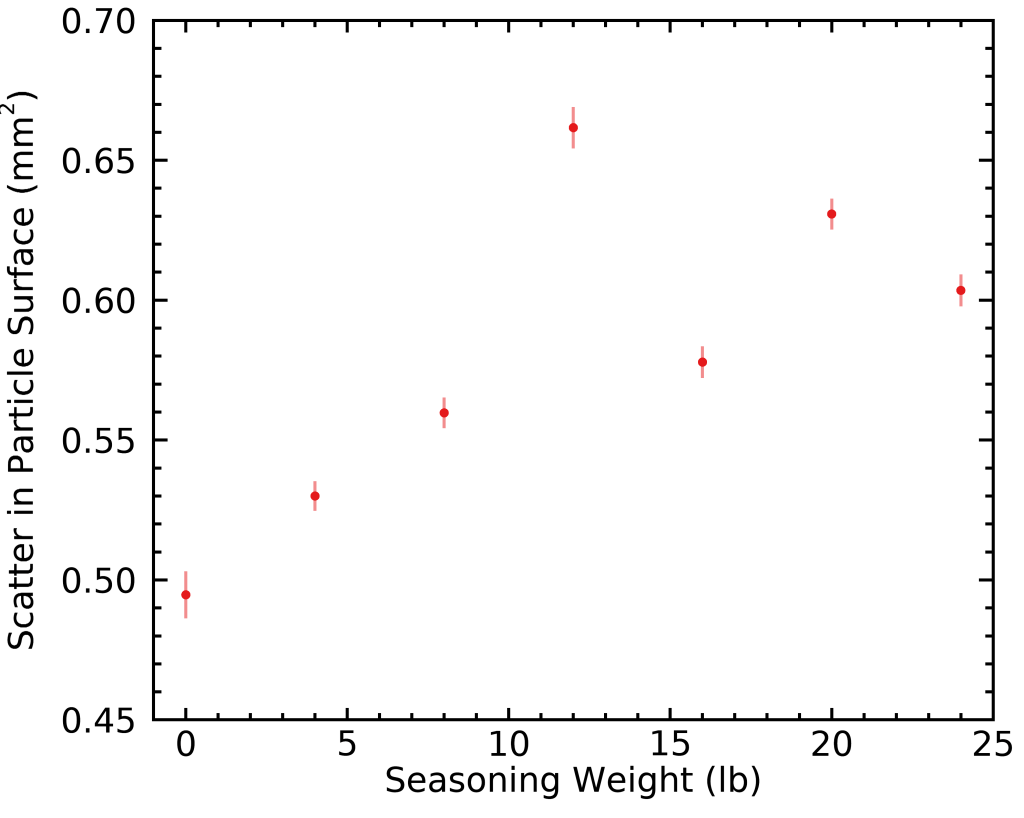

Another interesting relation to look at is how the width of the particle size distribution evolves with seasoning weight. I did this by looking at its standard deviation:

In the figure above, the error bars are similarly based on small number statistics. What we see here is a little different; the distribution initially becomes wider, but then it starts becoming narrower (more uniform). In my experience, particle size distributions that are centered on coarser particle sizes always seem to be wider. This is what led me to define something called the Q-factor (for “quality” factor) in my grind size app, which is simply the ratio of the average particle surface divided by the standard deviation of the particle surface distribution. This ratio seems to be relatively constant across grind sizes (at least in the neighborhood of filter brews), and it also seems to go up with grinder quality. I’ll get back to this in more detail in a future blog post, but here are typical Q-factors that I started compiling for different grinders:

- A friend’s Mahlkonig EK43* after aligning with shims: 1.45 ± 0.02

- Baratza Forté BG*: 1.53 ± 0.01

- My EG-1 with SSP burrs before seasoning: 1.59 ± 0.02

- An older EK43* model that another friend carefully aligned: 1.61 ± 0.01

- My EG-1 with SSP burrs after seasoning: 1.76 ± 0.02

An asterix indicates a grinder with its original stock burrs.[Update May 17 2019: Stay tuned for a more complete list of Q-factors that will evolve over time and be accessible to Honey Geisha-tier patrons.]

Gathering these data takes a tremendous amount of work, but I’m gradually building up a library of quality factors for different grinders that I managed to get my hands on. My Patreon followers can already access that partial list as I build it up, but I will eventually release it to the public; it will take a while for me to finish this up however.

This led me to think that a more interesting way to look at how my particle distributions evolve through seasoning is to look at their Q-factor versus seasoning weight:

As you can see, the Q-factor didn’t change much at first while the particle distribution shifted to coarser grind sizes (it hovered around ~1.55, similar to a re-aligned EK43), but then it started increasing by quite a lot.

Eventually, I will map out precise particle size distributions for several different grind sizes with my fully seasoned EG-1. This will allow me to compare each of the particle size distribution above with a fully seasoned distribution at the same average grind size, and thus to say more precisely how the distribution narrowed versus seasoning weight, without having to make the assumption that the Q-factor is perfectly independent of grind size. But this will also take many more seasons of The Office 🙂

More seasoning and an Interesting Observation

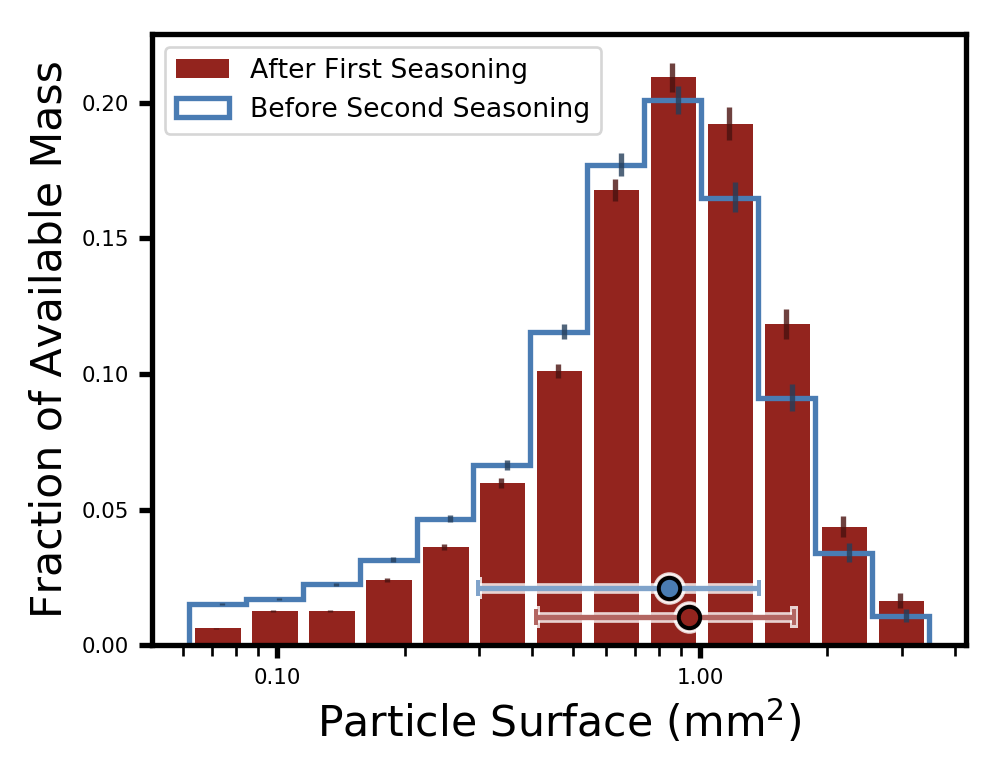

When I left my friend’s roaster place after having seasoned the EG-1 with 24 pounds of coffee, I grabbed a bit more of his Burundi and put it in a sealed opaque bag with a 1-way valve and an oxygen absorbing pad (see my other blog post about keeping your coffee fresh for why this is good practice). I did this with the plan to eventually season the grinder a bit more with a 4 pounds bag of bad coffee I had at home. It took me 23 days (and 3.5 pounds of filter pour over coffee that I actually drank) before I had the time to do so. Fortunately, I had the good idea to take a sample before this additional seasoning, as well as after. The effect of this additional seasoning on the particle size distribution was very small, as expected:

There is one thing that really surprised me however; if I compared the grind size distribution right before seasoning again to that right after my first seasoning, it actually became much finer and slightly wider, as you can see in this next figure !

It is highly unlikely that this was caused by the additional 3.5 pounds of coffee that I ground at filter size, because (1) grinding this coarse has a much smaller effect on breaking in the burrs; and (2) this goes exactly the other way than what seasoning does (as we saw above, it makes the particle distribution coarser and narrower, not finer and wider !).

My best hypothesis for what happens here is this: I think that the coffee beans de-gassed and dried as they aged, and the cellulose structure of the beans may also have weakened form the aging. All of these effects will make it easier for the beans to shatter, which will produce more fines, therefore shifting the particle distribution to finer average sizes and widening it. This is exactly what happens with decaffeinated coffee, which requires grinding at slightly larger grind sizes than regular coffee. This will be the subject of a different post, but some extensive blind-tasting dialing in had me select an optimal grind size of 7.5 (375 micron burr spacing) for Heart‘s Colombian decaffeinated coffee, whereas I selected 7.0 (350 micron burr spacing) for several different caffeinated beans; you can also see this nice coffee tip of the day from Scott Rao about brewing decaffeinated coffee.

I found this possible explanation so interesting that I plan to do more experimentation about it, to determine exactly how particle size distributions shift with aging. Imaging knowing exactly how coarser your optimal grind will change versus the age of your coffee, without needing to dial in again. I would definitely love that !

Disclaimer: Doug Weber generously offered me the SSP Ultra low fines burrs when I bought the EG-1 (under no obligations). I decided to get this grinder based on my friend Mitch’s recommendation and my own research on available grinders, and I receive no benefits from Lyn Weber.

Hi Jonathan,

When you say you divided the average surface area by the stddev, which stddev did you use? That under the average, or over the average, or were they equal? In sifting, an equivalent factor has been used for 70+years & is how the sieve intervals are determined.

Kind regards, Mark.

LikeLike

Hey Mark, I used the classical stddev, so it’s a in between the values of those above & below. I know it’s not a symmetrical distribution, but it’s still a useful metric. That’s interesting about sifting, thanks. Do they use this to determine the quality of the sift ? E.g. the stddev of the holes vs the average hole size ?

LikeLike

Hi Jonathan, well, you can use this as a rough guide to distribution tightness, or otherwise – better than/worse than a stddev factor of 1.4 for instance. You can also factor in the smaller intervals too with factors of ~1.18/1.19. ASTM/ISO sieves are built to certain tolerances.

Kruve stddevs tend to be wider & less linear as you go finer, but still repeatable & broadly informative given a more specific target range of grind size.

LikeLike

Thanks ! I’m not surprised sieves use the same metric, it’s far from being very creative 🙂

LikeLike

Hi there, on EG-1 website, there is a seasoning guide that suggests using 300g of rice. Perhaps that’d be more economical for people without access to cheap beans?

LikeLike

Yes, I’ve often heard rice is a viable option. 300 grams sounds like a small amount, I needed 10-12 pounds of coffee for the grind size to stabilize

LikeLike

Perhaps it’s because rice is much harder – there are some posts in the past actually warning against using rice (for which grinder i cannot remember)

How do you find the upgrade from Forte to EG-1 so far?

Cheers

LikeLike

That’s totally possible yes. I love the upgrade ! It’s really expensive but damn impressive.

LikeLike

I am looking into EG-1 as well, and I am trying to figure out whether it justifies the cost compared to forte as I am only using v60 and kalita atm

Good to know you have a positive experience!

LikeLike

It just depends on how much you’re willing to spend to improve your cups. It’s definitely better than the Forté, but in this range of top tier grinders, cost goes up fast for every increment in quality, like in all other things. I don’t regret it !

LikeLike

Hi Jonathan, Scott Rao said in a video for seasoning the grinder “put a few kilos through on the absolute finest settings” , which I think you didn’t do here, what is your opinion? Also what do you think about seasoning burrs with parboiled rice? Thanks

LikeLike

Finer grind size would probably have seasoned faster, but back then I didn’t know the EG1 well enough to do it properly. You need higher RPM with super fine grind to avoid motor jam.

LikeLike

Hey Jonathan, how are you? I came back to this post because I just got a new Baratza Forte BG; I sent my old one back to Baratza because of a warranty issue. I am currently seasoning the burrs. Do you recommend seasoning at espresso grind size e.g. right before burrs touch? Also, should I take a break to let the burrs cool down as I grind? The coffee grounds can get above room temp as I grind a few hundred grams off coffee in pretty much one go. By the way, I love that your coffee science is getting recognized more and more by the greater coffee world. Keep it up. Hope you and your family are doing well given the current situation.

LikeLike

Hey ! Yes I would use about espresso grind size, a fine grind size will season it faster. I would wait a bit when it gets warm, just not to overheat the motor – it doesn’t matter too much that the grinds get warm.

LikeLike

Hey Jonathan.

I’m looking to upgrade my Forte BG and am weighing going with an EG-1, a Ditting Lab Sweet, or holding out for the Nautilus filter grinder from Titus. When you decided on the EG-1 did you also take a look at the Lab Sweet?

LikeLike